Have any questions?

+44 1234 567 890

Technological lead through innovative nozzle engineering

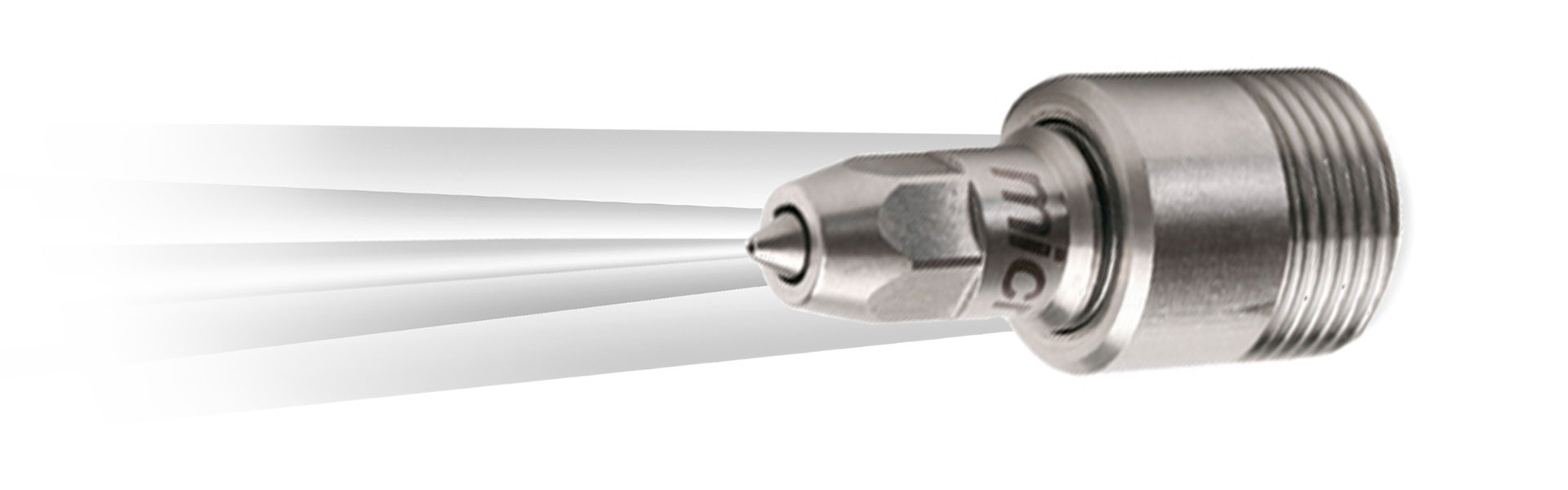

The patented two-phase nozzle features an internal mixer chamber in which the liquid is atomized using compressed air. Simultaneously, the compressed air flows within an annular channel parallel to the mixing chamber and forms an air jacket/air bell when escaping out of the nozzle end.

- Most precise and directional stable mixture jet

- Mixture jet directed to the machining point within an air jacket

- No nebulizing of liquids

- Low noise level

- Minute compressed air consumption in comparison with conventional needle nozzles

- Application of reproducible quantities

- Reliable metering of both low- and high-viscosity liquids

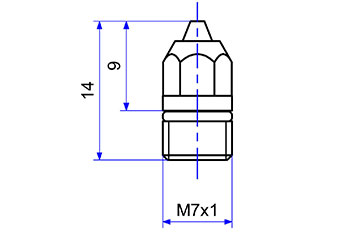

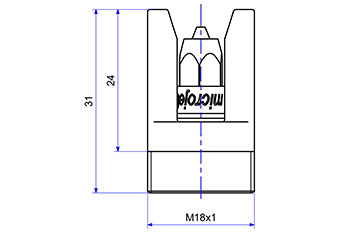

Two-phase nozzle Ø 7 mm

Properties: Small sizes for applications within reduced mounting space.

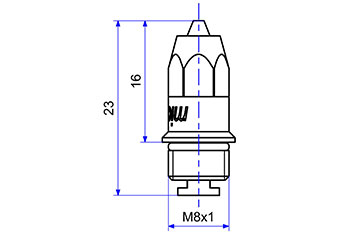

Two-phase nozzle Ø 8 mm

Properties: Standard nozzle, dense spray Jet.

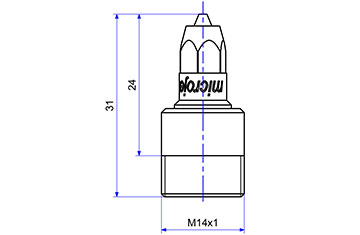

Two-phase nozzle Ø 8 mm with air jacket generator

Properties: Additional air bell, accurate narrow spray Jet.

Two-phase nozzle Ø 8 mm with air jacket generator

Properties: Wide spray jet, spraying width up to 50 mm, also suitable for high-viscosity liquids (up to 400 mm2/s)

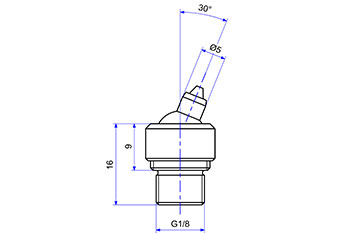

Articulated nozzle Ø 4.4 mm.

Properties: tiltable by 30°, rotatable by 360°, narrow spray jet. For short distances and low-viscosity liquids.

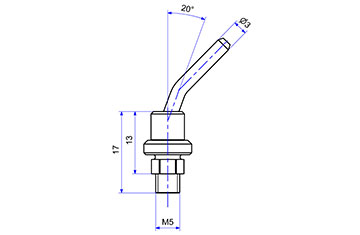

Articulated nozzle short.

Properties: Small size, tiltable by 60°,rotatable by 360°.

Articulated nozzle, long.

Properties: Standard nozzle, tiltable by 60°, rotatable by 360°. Dense spray jet up to 200 mm.

Atomizing nozzle

for lubrication through the tool spindle.