Have any questions?

+44 1234 567 890

Oiling of wires, tubes and boards

microjet ® minimum-consumption lubricating technology allows to wet tubes, wires, profiles and boards through finest metering of any liquid.

To avoid striation and tool wear during the forming process tubes, wires and profiles have to be previously oiled with medium. After the machining process the halffinished product manufactured Always has to be coated with a protective film to avoid superficial damages and other depreciating effects. microjet ® nozzle technology atomizes the liquid into finest particles (microscopic particles) using compressed air. This generates a large uniform thin layer of fluid (layer thickness 0.2 to 5 μm) that extremely well adheres to the surface of the workpiece.

The compressed air additionally promotes the penetration of the microscopic particles into the superficial “pores” of the workpiece. The liquids applied are thus able to unfold their properties to the full.

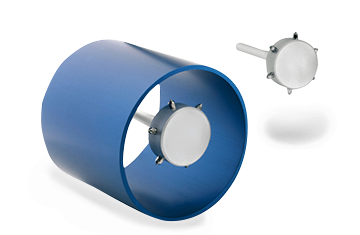

Internal lubrication of tubes

The spraying unit is passed through the workpiece to be oiled.

External lubrication of tubes

The workpiece to be oiled is passed through a spraying gate.